Slide 1

Tooling Solutions for Innovative Companies

Our long-lasting and reliable tool solutions improve our world by helping to supply critical plastics components for key industries of our modern society. We take great pride in participating in applications that positively affect people's lives.

We combine the latest technology with the highest quality machining to deliver world class molds faster than anyone else.

Ruediger Kuemmerle

Managing Director

About Us

Tooling Solutions for Innovative Companies

Precision and Performance. Our international team of experts ensure our clients are completely satisfied with their mold solution. It’s how we have earned our reputation of going the extra mile to make sure your project is a complete success. Our range of services include feasibility studies, design for manufacturability, 3D modeling and prototyping, mold manufacturing, start up support to final mold validation. We also provide in-house engineering changes, preventive, corrective & predictive maintenance as well as repairs. Our strong focus on environmental awareness results in our pursuit to reduce waste and our commitment to providing lasting value.

Cap abilities

Tooling Solutions for Innovative Companies

Injection Mold Design & Fabrication

- Feasibility studies

- Design for manufacturability

- 3D modeling and prototyping

- Mold manufacturing

- Start up support to final mold validation

- In-house engineering changes

- Preventive, corrective & predictive maintenance as well as repairs

Global network providing high quality plastic injection Mold, Tool and Die manufacturing and procurement.

Project Examples

Please contact us for more information

- RNA collection device

RNA Collection Device

Prototype to Mass Production in only 6 weeks

“Formula, are you ready for your next fire drill…”

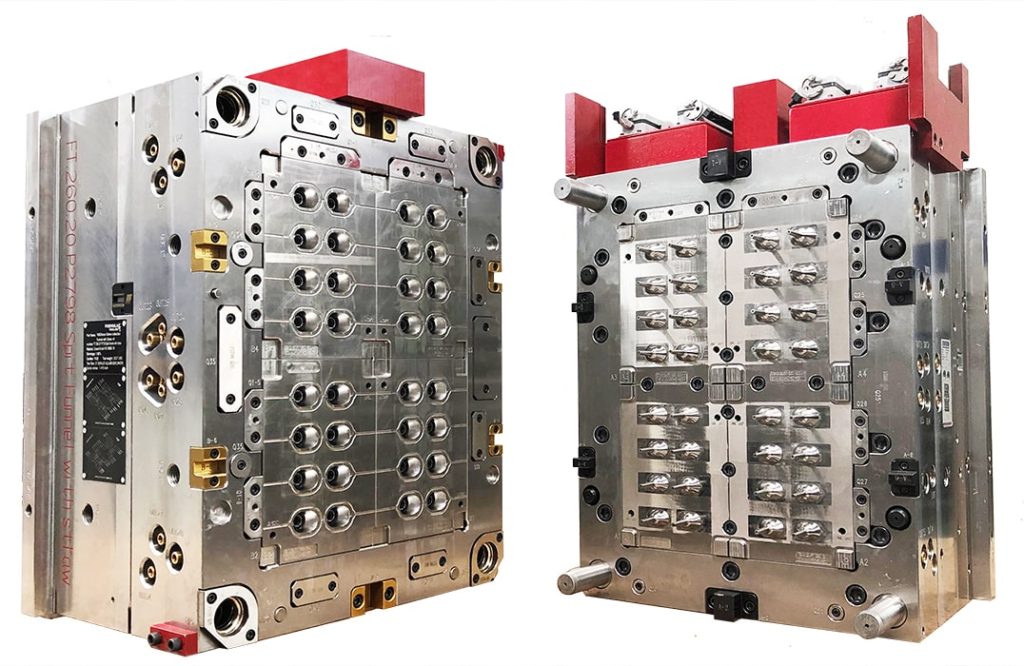

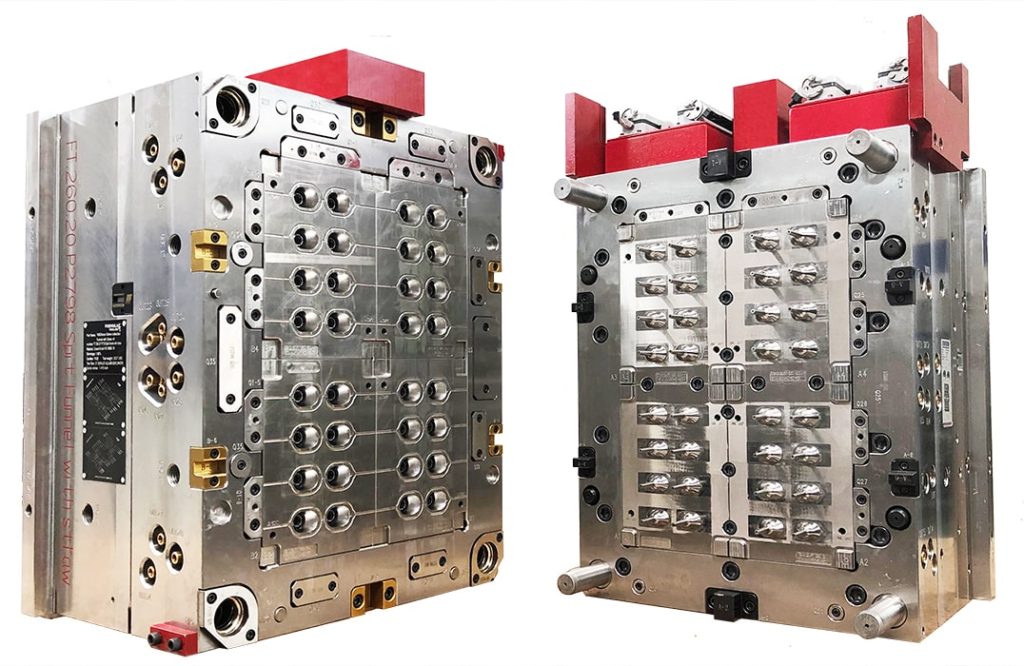

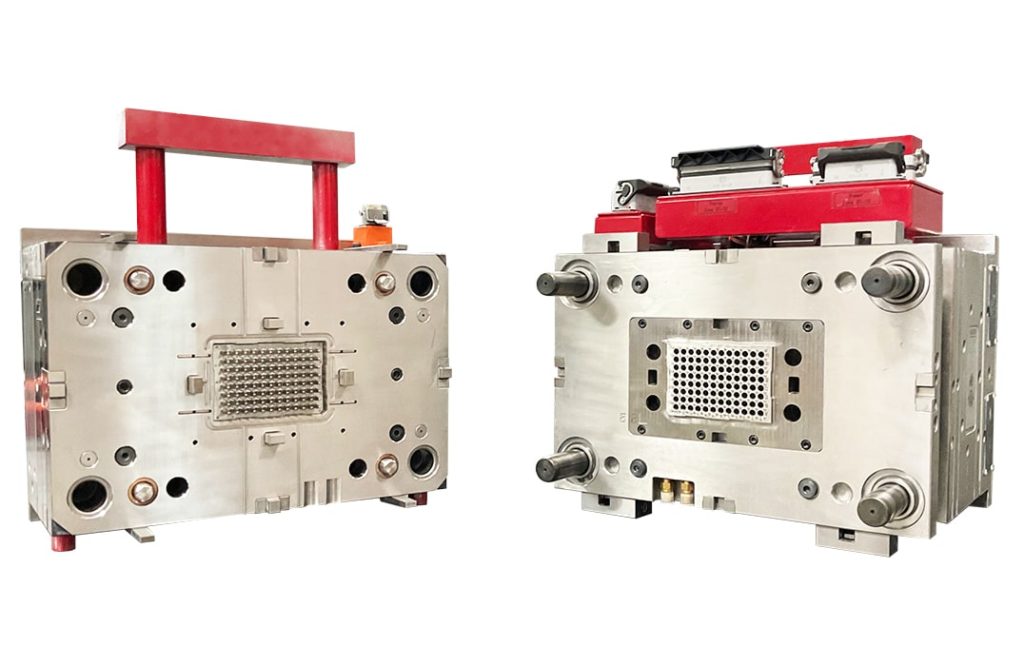

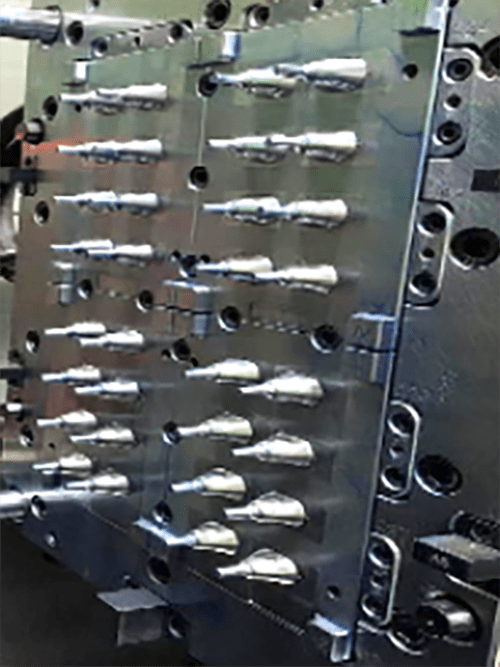

Formula Tooling, known for responsiveness and a top-quality solutions, recently completed the tooling for a 32 cavity mass production mold for the production of an RNA collection device – most commonly known as a spit funnel.

The turnaround time was critical in this application and within a week from receiving the client data, prototype samples were sent out to the client in the US. A Class 105 single cavity mold was developed with manual hand out on ejection side, and a 3 plate pin point to simulate the hot tip.

With approval of the prototype sample and receipt of the formal PO for mass production, it took less than 5 weeks to prepare the mass production mold samples for the client. A 32-cavity Class 101 mold was built; completely stainless-steel construction suited for clean room operations. The fully integrated hot half included 32 open nozzles from Germany and fully hardened cavities and cores.

The passionate design and fabrication team at Formula Tooling take great pride in participating in applications that positively affect people’s lives.

Contact us for more information.

[email protected]

Loc ations

Our mold, tool & die procurement includes expertise from all over the globe.

Tecate / Mexico

Formula Tooling

Headquarters

Hong Kong S.A.R

Strategic Tooling Partner

Shenzhen / P.R. China

Formula Tooling

Facility 1

New Delhi - India

Strategic Tooling Partner

Dong Guan / P.R. China

Formula Tooling

Facility 2

Fitchburg, MA – U.S.A.

Strategic Tooling Partner

Car eers

We are always looking to add top talent to our team of passionate professionals. See below for current openings.

Contact Us

Address

Guaycura #106, Col El Paraiso,Tecate BC, 21485, Mexico